- Home >

- ITMRL >

- Laboratories

- > Intelligent Machinery Condition Monitoring Laboratory

Intelligent Machinery Condition Monitoring Laboratory (IMCML)

PURPOSE: Fault Diagnostics & Prognostics

Diagnosis is the identification of the nature and cause of problems in systems. Diagnosis is used in many different disciplines with variations in the use of logics, analytics, and experience to determine the cause and effect relationships. Such disciplines encompass an array of electro-mechanical problems such as: complex manufacturing systems, aircrafts, power generating equipment, turbo-machinery, electro-mechanical systems, computer-based networks, and autonomous robotic systems.

In electromechanical systems, diagnosis is typically used to determine the causes of symptoms, mitigations for problems and solutions to problems generally induced due to excessive vibration, strains/stresses, and thermal growth in electro-mechanical systems.

Prognostics is an engineering discipline focused on predicting the time at which a system or a component will no longer perform its intended function. This lack of performance is most often a failure beyond which the system can no longer be used to meet desired performance. The predicted time then becomes the Remaining Useful Life (RUL), which is an important concept in decision making for contingency mitigation.

Prognostics predicts the future performance of a component by assessing the extent of deviation or degradation of a system from its expected normal operating conditions. The science of prognostics is based on the analysis of failure modes, detection of early signs of wear and aging, and fault conditions. These signs are then correlated with a damage propagation model.

Potential uses for prognostics is in condition-based maintenance. The discipline that links studies of failure mechanisms to system lifecycle management is often referred to as prognostics and health management (PHM), sometimes also system health management (SHM) or - in transportation applications - vehicle health management (VHM). Technical approaches to building models in prognostics can be categorized broadly into data-driven approaches, model-based approaches, and hybrid approaches.

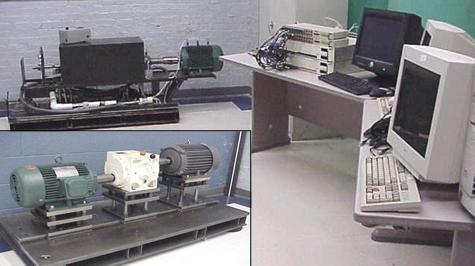

IMCM research laboratory at the Department of Mechanical and Manufacturing Engineering was established in 1998 with the initial funding support from Office of Naval Research and National Science Foundation. The IMCM research lab hosts several small to large-scale experimental test beds for conduct of machinery condition monitoring for the purpose of fault diagnostics and prognostics.

RESEARCH FOCUS

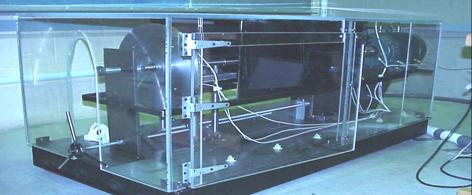

The IMCM research focus is towards development of next generation machinery diagnostics and prognostics techniques that are both intelligent and performing robustly. The laboratory testing equipment includes: a turbo-fan system, an electric magnetic bearings, a bearing test bed, a motor-pump-load system, an industrial-grade shaker system, and a number of other smaller scale experimental test beds. The research thrust of IMCM lab is toward development of advanced signal processing and AI technology integrating data from multi-modality sensors for intelligent detection and diagnostics of faults in electromechanical machinery. Another objective is to develop validated prognostics model for rate of growth estimation of the defects in machinery system and related such parameters to remaining useful life of the system.

COLLABORATING WITH PARTNERING INSTITUTIONS

The IMCM has been a research collaborator with Penn State University (PSU) Applied Research Laboratory (ARL). The researcher at IMCM lab develop advanced signal processing techniques in conjunction with soft computing technologies (i.e., neural networks, fuzzy logics, and genetic algorithms) for machinery fault diagnostics and prognostics applications. The IMCM laboratory is equipped with variety of machinery health monitoring sensors and systems.

COURSE OFFERINGS

The graduate manufacturing engineering program at TSU offers several graduate level courses in the area of machinery vibration control, fault diagnostics and prognostics, and advanced signal processing. The interested students are encourange to contact us to learn more about this program.

webpage contact:

ITMRL